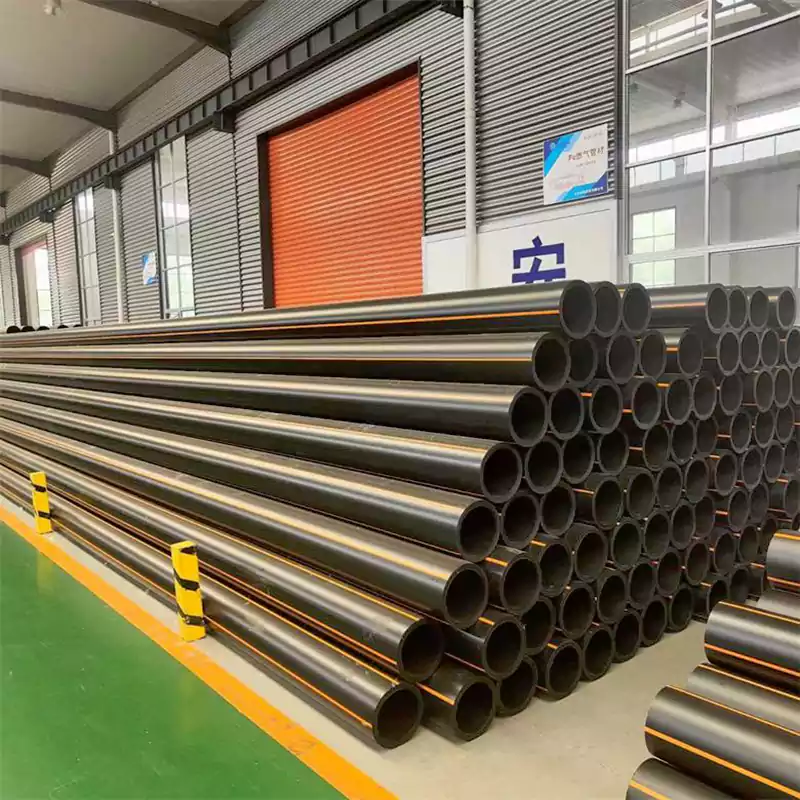

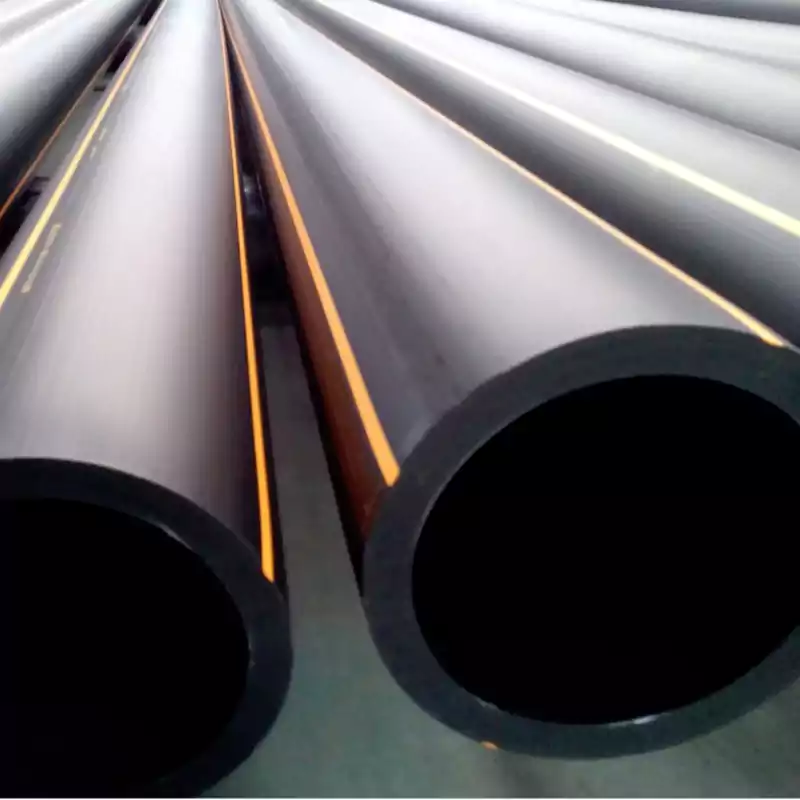

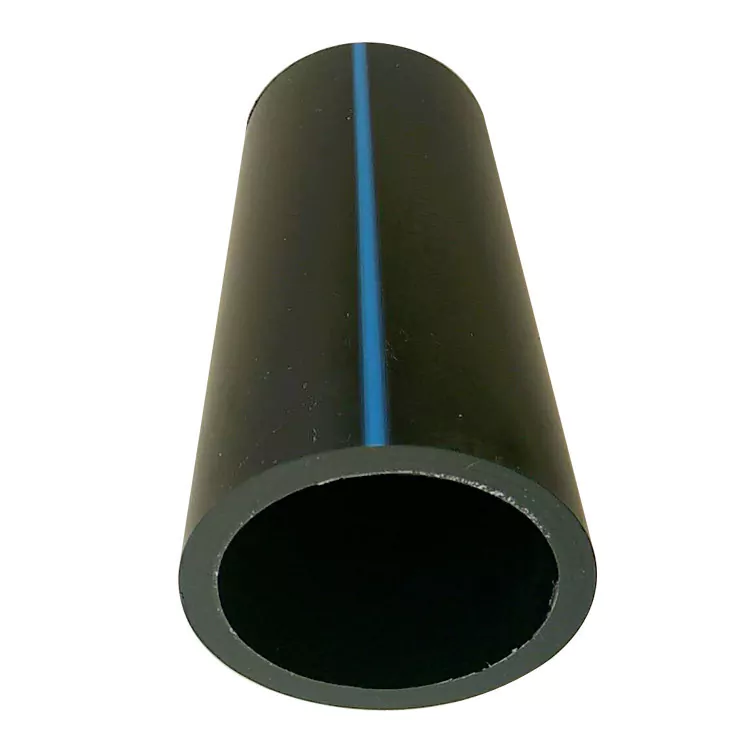

Yellow line HDPE gas pipes are specialized pipes designed for transporting natural gas and propane in underground distribution systems. The yellow color is a universal indicator for gas piping, ensuring easy identification during installation and maintenance.

Yellow line HDPE gas pipe has high impact resistance, even under low temperatures, and is resistant to corrosive chemicals and aggressive soils. It is a flexible product, easy to handle, install and joint fuse due to longer lengths and even surface finish. Other benefits include: corrosion resistance, extreme weather resistance, slow crack growth resistance, abrasion resistance, flexibility for earthquake prone areas, satisfactory fusion joints, and long service life. It could be apt to survive severe ground shifts, especially from earthquakes, when they are made from fused PE pipe joints.

The main advantages of using yellow line HDPE gas pipe

- Corrosion Resistance: Yellow line HDPE gas pipe is immune to corrosion, unlike metal pipes, which can degrade over time when exposed to moisture or chemicals.

- Flexibility: HDPE pipes are flexible, which makes them easier to install, especially in areas with challenging terrain or where other piping materials would require more fittings.

- Strength and Durability: HDPE has a high tensile strength and can withstand pressures typical for gas systems. It is also resistant to cracking and impact.

- Leak Prevention: HDPE pipe joints are typically fused together using heat, which creates a monolithic, leak-free system without the need for mechanical fittings or seals.

- Cost-Effectiveness: HDPE pipes are often more affordable than metal pipes, and their lightweight nature reduces transport and installation costs.

- Long Service Life: HDPE pipes have a long service life (up to 50 years or more) with minimal maintenance required.

- Safety: Since HDPE is a non-toxic material, it is safe for transporting gases without the risk of contaminating the gas or water supply.