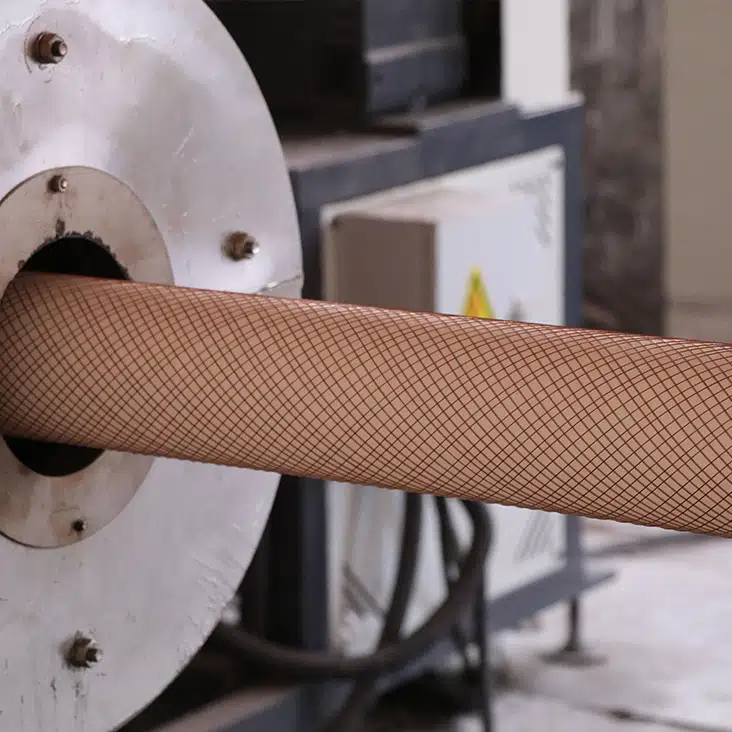

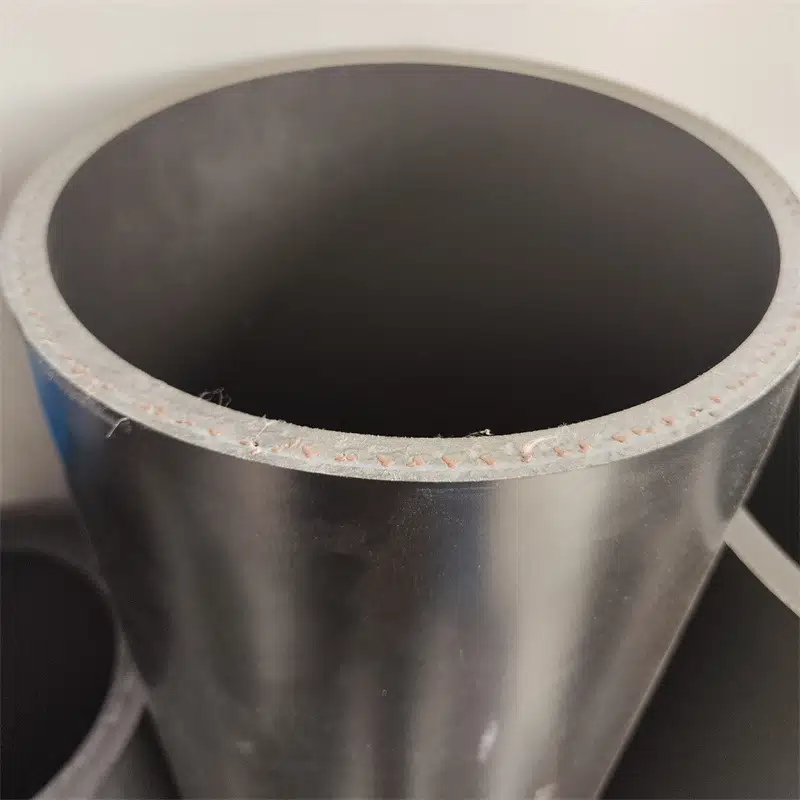

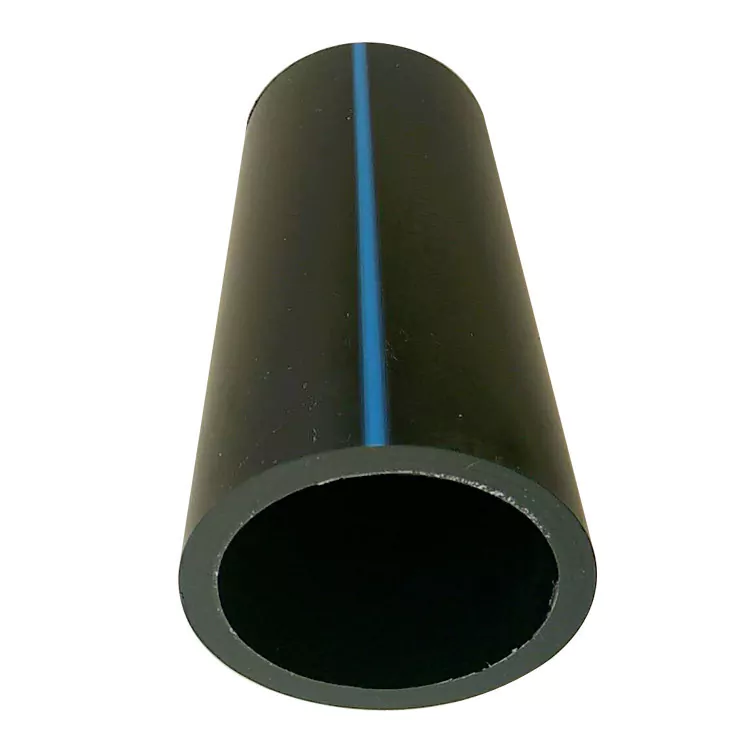

Steel Wire Mesh PE Pipe is the new type of pipe, made of high-strength plasticized steel wire mesh and high-density polyethylene as raw materials. The steel wire mesh is used as the skeleton reinforcement of the polyethylene plastic pipe. It uses high-density polyethylene (HDPE) as the matrix and uses high-performance HDPE modified adhesive resin to tightly connect the steel wire skeleton with the inner and outer layers of high-density polyethylene.

It successfully solves the problem of no connection factor between steel and polyethylene, making it have an excellent composite effect. Because the high-density steel wire reinforcement is coated in continuous thermoplastic plastic, this composite pipe overcomes the shortcomings of steel pipes and plastic pipes, while maintaining the advantages of steel pipes and plastic pipes.

The main advantage of Steel Wire Mesh PE Pipe

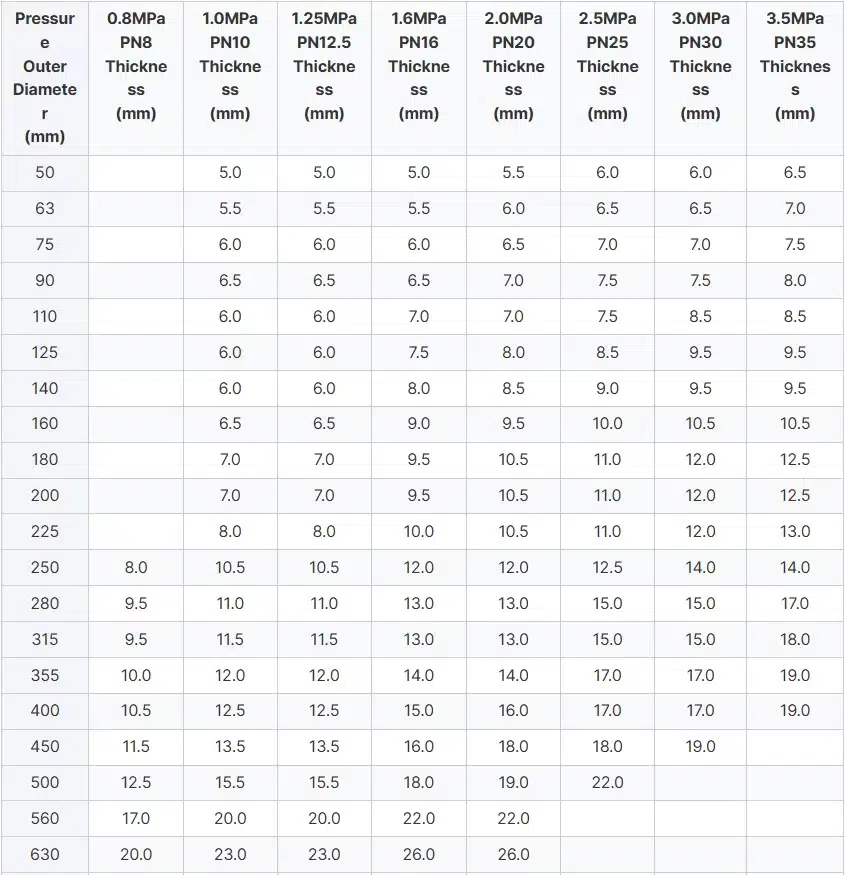

- High Strength: The steel wire mesh reinforces the pipe, making it resistant to high internal and external pressures.

- Corrosion Resistance: The PE layers provide excellent resistance to chemical corrosion and scaling.

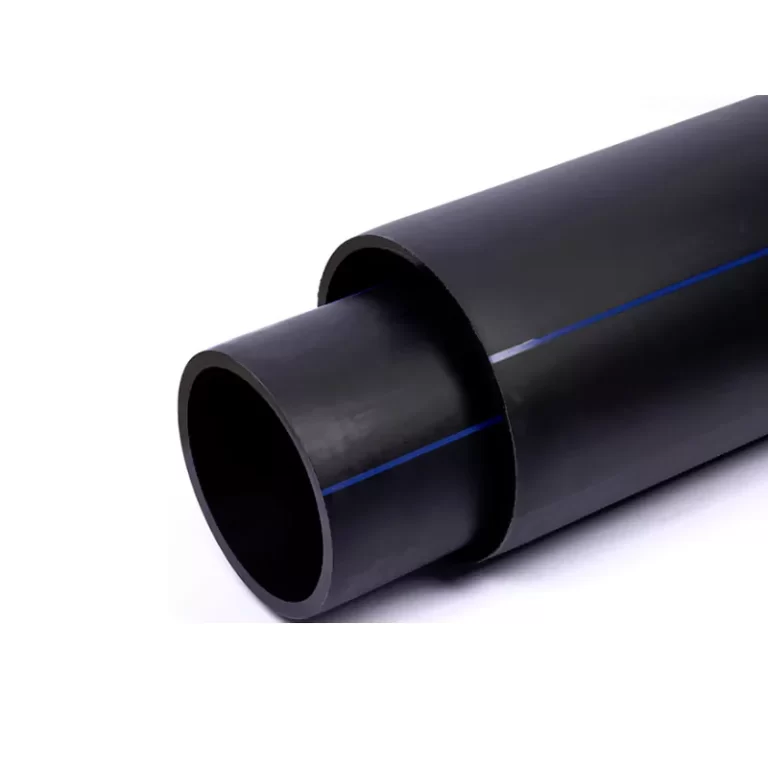

- Flexibility: The composite nature of the pipe allows it to maintain flexibility, making it easier to install than rigid metal pipes.

- Durability: Long service life due to the combination of robust materials.

- Lightweight: Compared to solid steel pipes, these are lighter and easier to handle.

Steel wire mesh PE pipe offer an advantage over traditional steel or PE pipes by combining the best properties of both materials. They are particularly useful in situations where high pressure, corrosion resistance, and lightweight properties are required.