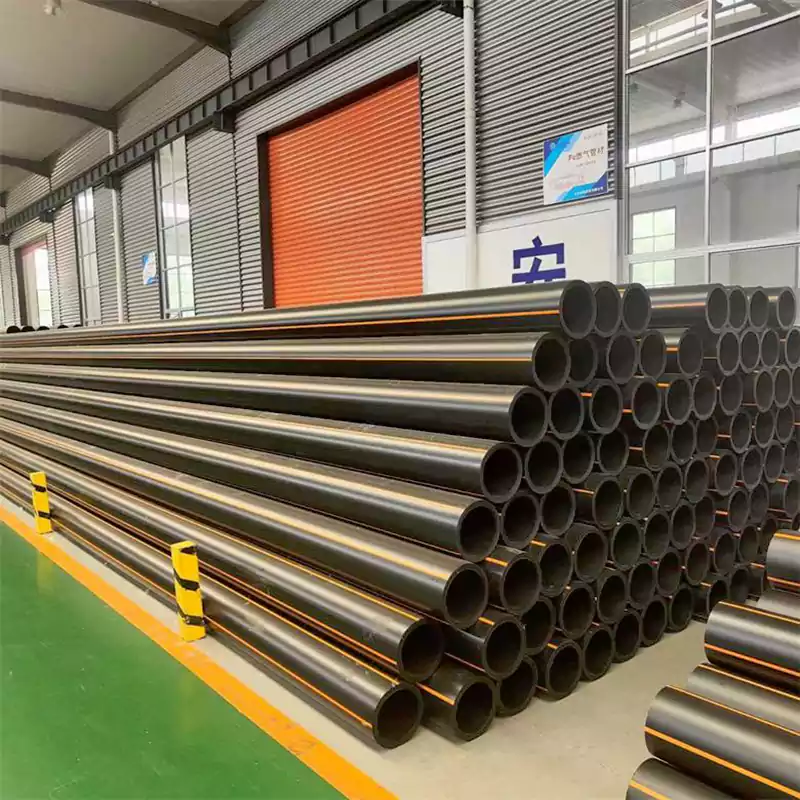

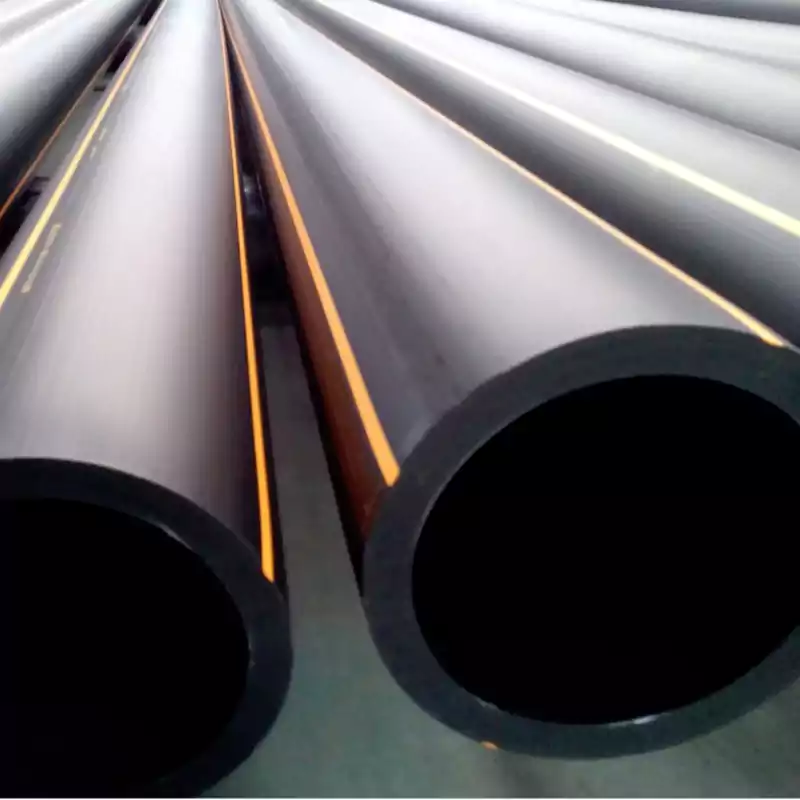

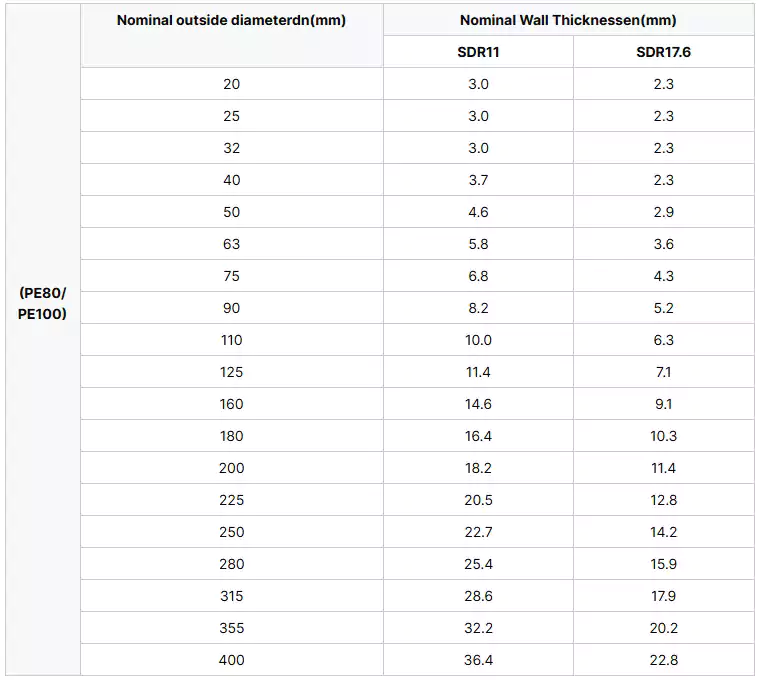

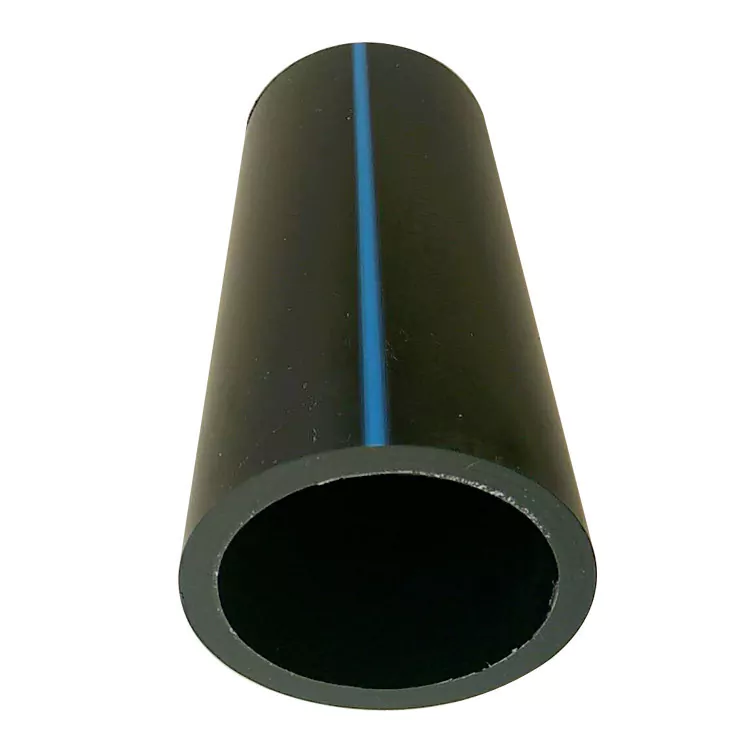

Hdpe Gas Pipe is commonly used for gas distribution systems, primarily due to their durability, flexibility, and resistance to corrosion. They are suitable for transporting natural gas, propane, and other gaseous fuels. It includes PE 80 (Black and Yellow) and PE 100 (Black and Orange) two series, SDR 17.6 and SDR 11 with DN 20-400 full specification pipes, commonly used pipe fittings, ball values and related supporting pipe products.

The main advantages of using hdpe gas pipe

- Corrosion Resistance: HDPE gas pipe is immune to corrosion, unlike metal pipes, which can degrade over time when exposed to moisture or chemicals.

- Flexibility: HDPE pipes are flexible, which makes them easier to install, especially in areas with challenging terrain or where other piping materials would require more fittings.

- Strength and Durability: HDPE has a high tensile strength and can withstand pressures typical for gas systems. It is also resistant to cracking and impact.

- Leak Prevention: HDPE pipe joints are typically fused together using heat, which creates a monolithic, leak-free system without the need for mechanical fittings or seals.

- Cost-Effectiveness: HDPE pipes are often more affordable than metal pipes, and their lightweight nature reduces transport and installation costs.

- Long Service Life: HDPE pipes have a long service life (up to 50 years or more) with minimal maintenance required.

- Safety: Since HDPE is a non-toxic material, it is safe for transporting gases without the risk of contaminating the gas or water supply.