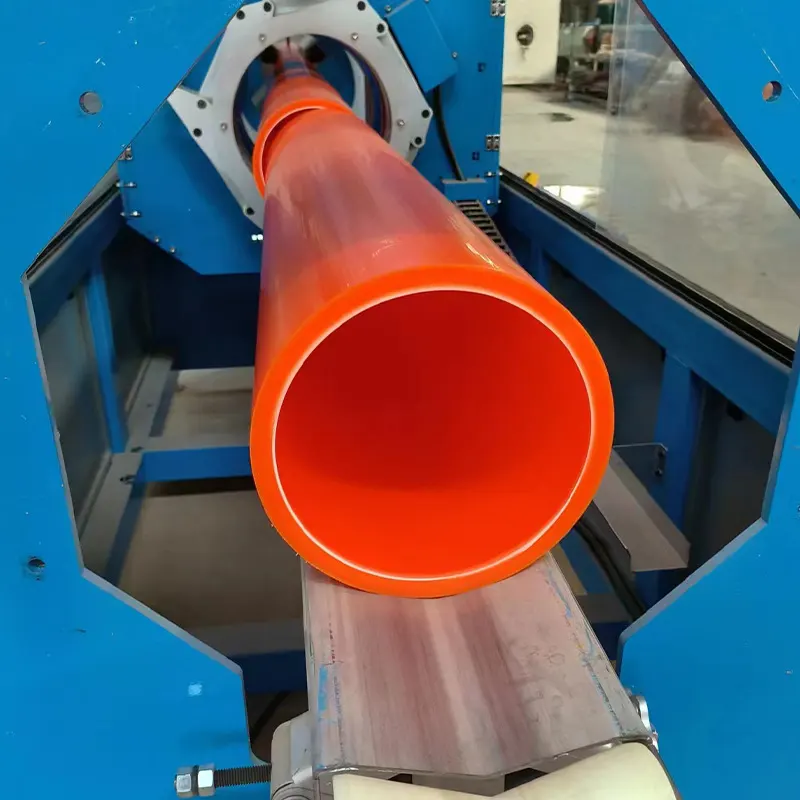

MPP cable conduit pipe for power cables is a new plastic pipe made of MPP with special formulation and technique. It has a series of advantages, such as high strength, good stability , easy cable threading, simple construction and cost saving. With outstanding advantages during pipe jacking construction, the product meets the development requirements of modern cities. Trenchless technology is adopted for the construction of MPP power cable sleeves, which not only protects the pipe line network reliability, reduces its failure rate, but also greatly improves urban environment.

MPP (modified polypropylene) underground electrical conduit for electrical communication cable protection is manufactured as the new type of plastic pipe adopting modified polypropylene as the main raw material and using a special formula and processing technology, with good features of high strength,temperature resistance, handling easily,convenient installation and cost saving. The modified polypropylene trenchless pipe is widely used as the protection pipe of electrical communication cable. Its characteristics is more obvious as a towing pipe. It conforms to the development requirements of modern cities and is suitable for buried depth of 2~18m.

The technical features of MPP cable conduit pipe

- Excellent electrical insulation performance.

- High thermal deformation temperature and good low-temperature impact resistance.

- The tensile and compressive resistances are higher thanthose of HDPE.

- Light weight, smooth, low friction resistance, and butt-type heat fusion welding is available.

- Long-term working temperature range : -5-70℃.

MPP cable conduit pipe (Metallic Polypropylene Pipe) is a specialized type of conduit used to protect and route electrical cables and wires, especially in outdoor, industrial, or underground installations. These pipes are known for their strength, durability, and suitability for harsh environments.