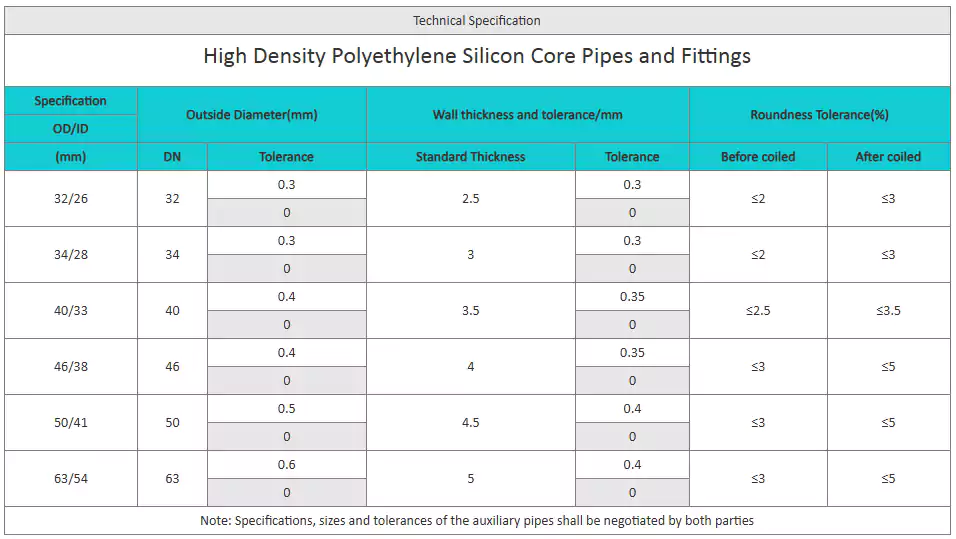

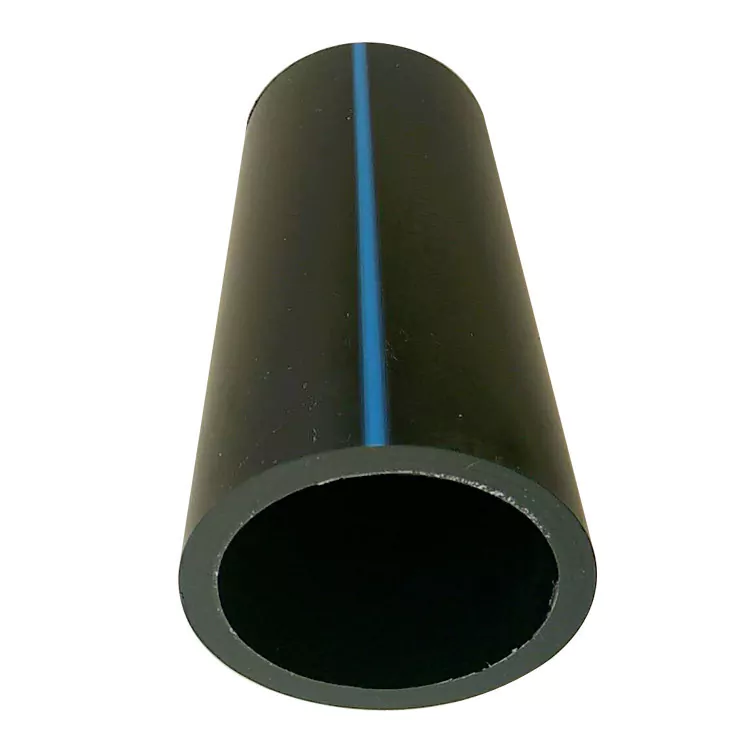

HDPE silicon core pipe are specially designed to be communication optical (electric) cable protection tubing. The silicon core pipe is produced and shaped through an extruding synchronization with the silicon core material and a low friction coefficient inside the HDPE pipe. Because of that, the HDPE silicon-core pipe provides excellent covenience for cable laying due to the durability and low friction coefficient inside the lubricating solid tunnel. It is among the most advanced methods for optical cable protection in the world today.

HDPE Silicon core pipe is a new type of composite pipe with a Silicone Solid Lubricant on the inner wall.it is widely used in optical fiber cable communication network systems for highways and railways. Synchronous extrusion compounding is carried out by three plastic extruders. The main raw material is high-density polyethylene, and the core layer is a solid lubricant silica gel with the lowest friction coefficient. And the third step is the laser strip coloring of the pipes.

The main advantages of HDPE silicon core pipe

- The inner wall of the HDPE silicon core tube is a solid, permanent lubricant;

- The inner silicon core layer of the HDPE silicon core pipe is extruded together with the high-density polyethylene pipe wall and is evenly distributed on the entire pipe inner wall without peeling or detaching. It has the same life as the silicon pipe; the cable can be repeated in the pipe.

- The inner silicon core layer of the HDPE silicon core pipe has the same physical and mechanical properties as the high-density polyethylene;

- The friction characteristics of the silicon core layer on the inner wall of the HDPE silicon core pipe remain unchanged, and the cable can be repeatedly extracted in the pipe;

- The inner silicon core layer of the HDPE silicon core pipe does not react with water, and water can be used to flush the pipe after an accident.

- Silicon core tube has a small radius of curvature (ten times its outer diameter)

- The bends and drops encountered during pipe laying can be determined according to the environment and terrain without any treatment.

- The construction is convenient, and the project cost is greatly reduced: the silicon core tube does not need to be jacketed with a large tube, and the cable can be directly threaded in the pipeline without the need for sub-pipes.

- Directly buried fiber optic cable casing, with a permanent lubricating lining on the inner wall, with a smaller friction coefficient. The air blowing method is used to lay out the fiber optic cable. The tube is laid quickly. The length of the one-time cable can reach 500 meters to 3000 meters. The joints and manholes along the line The hand hole is reduced accordingly.

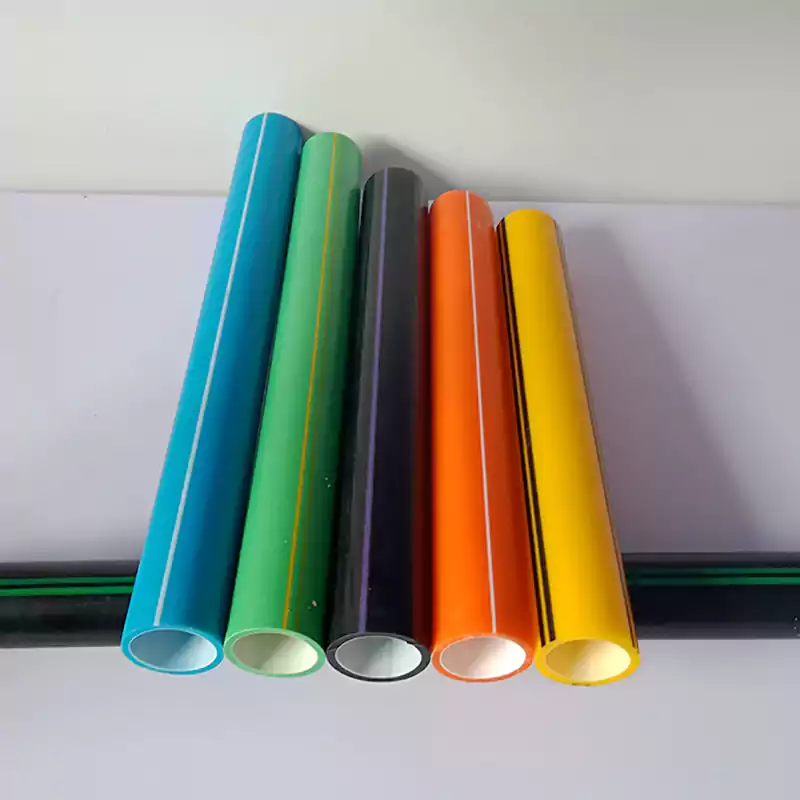

- The tube has 18 kinds of colors could be option, and the tube body can be attached with four marking color.

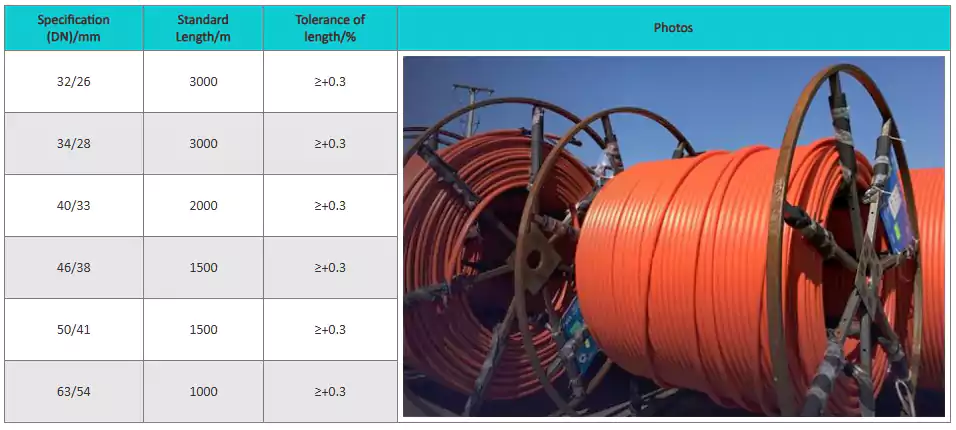

- The length of each length or roll silicon core tube can be made by any length as requirement.