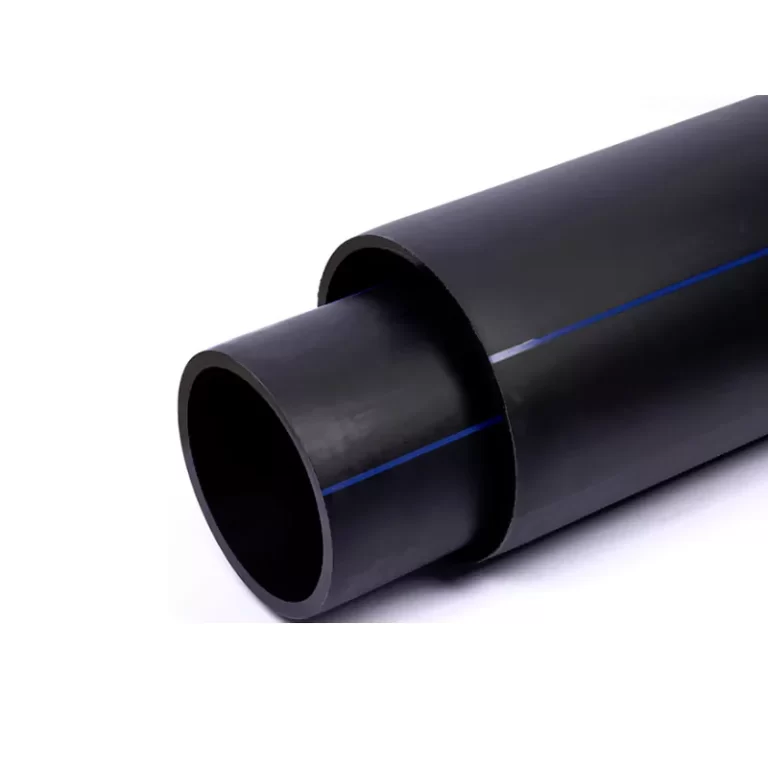

HDPE pipe plastic tube is made of high density polyethylene resin. The product’s physical properties make it applicable to open-trench, horizontal directional drilling, pipe-bursting and slip-lining installations. It can be manufactured with the color striping to identify application, such as a blue stripe for potable water, a yellow stripe for gas applications and a red stripe for mining applications. HDPE pipe plastic tube can carry potable water, wastewater, slurries, chemicals, hazardeous wastes, and compressed gases. Polyethylene is strong, extremely tough and very durable.

Benefits of HDPE pipe plastic tube

- Chemical Resistance: Studies show that HPDE pipe will not corrode or tuberculate, maintaining flow velocities over the life span of the system.

- Durability and Flexibility: HDPE pipe is a more durable and flexible pipe material with a bend radius up to 20 times the pipe diameter. This allows the HDPE pipe to conform to an imperfect installation path without the need to add costly fittings and excessive pipe joints.

- Extreme Surge Tolerance: HDPE pipes are the most resistant to surge and fatigue of any potable water piping systems. HDPE pipe can handle much higher flow velocities which result in lower pressure surges compared to other potable water piping systems.

- Temperature Resistance: HDPE pipe can handle fluid and environmental temperatures ranging from -40°F to 140°F, making HDPE water pipe suitable for use with hot or cold water in many different environments.

- Installation: HDPE pipe is cheaper to install than other potable water piping systems. Could be installed with trench-less technologies (directional drilling, pipe bursting, slip-lining, and compression fit lining), making HDPE pipe the most commonly used piping material for trenchless installations, greatly reduce the amount of construction restoration, leading to a cost savings up to 65%.