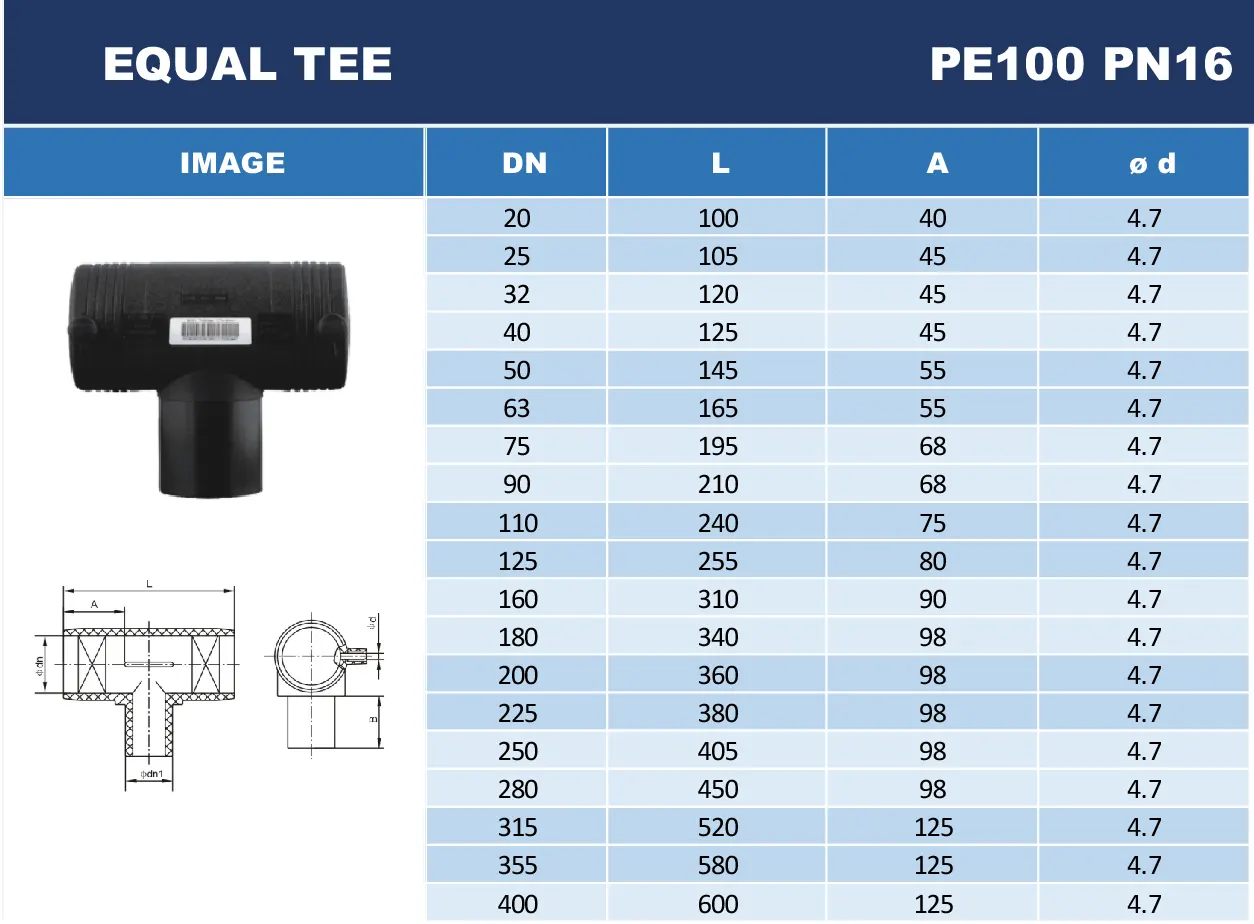

HDPE electricfusion equal tee is used to split a HDPE pipe into two outlets at right angles to the end of the original pipe, or to add in an outlet to a PE Pipe. Electrofusion equal tees are made with an equal size pipe diameter on all three ends. With a size range from 20 mm to 180 mm, electrofusion equal tee fittings come in SDR 11 (which also suits SDR 13.6 & SDR 17).

HDPE electricfusion equal tee fittings are made from PE 100 material with a precisely moulded energising coil of wire, ensuring uniform melting for a strong electrofusion joint and the minimisation of welding and cooling times. SDR 11, SDR 13.6 and SDR17 electrofusion equal tees are rated to PN16 water and 1000 kPa gas. Equal tee electrofusion fittings are suitable for use for HDPE pipe, and welded with an electrofusion pressure welder. Electrofusion equal tee PE fittings may also be known as an electrofusion equal tee joiners or equal tee pipe joiners. Note that the centre of the tee is a spigot fitting and requires a coupler to join it to another pipe or fitting.

The main features of HDPE electricfusion equal tee

- Material: High-Density Polyethylene, which is durable, corrosion-resistant, and suitable for various applications such as water supply, gas distribution, and industrial pipelines.

- Electrofusion Technology: Fitting contains built-in resistance wires that, when connected to an electrofusion machine, heat and melt the material to fuse it securely with the pipes.

- Equal Tee: The term “equal” indicates that all three openings of the tee are the same diameter, ensuring uniform flow distribution.

The installation of HDPE electricfusion equal tee

- Preparation: Clean and dry the pipe ends and fitting and mark the insertion depth on the pipe.

- Alignment: Insert the pipes into the tee fitting until they meet the depth marks.

- Fusion:

- Connect the electrofusion machine to the fitting’s terminals.

- Follow the manufacturer’s instructions to apply the specified voltage and time.

- Cooling: Allow the joint to cool naturally before moving or pressurizing the system.