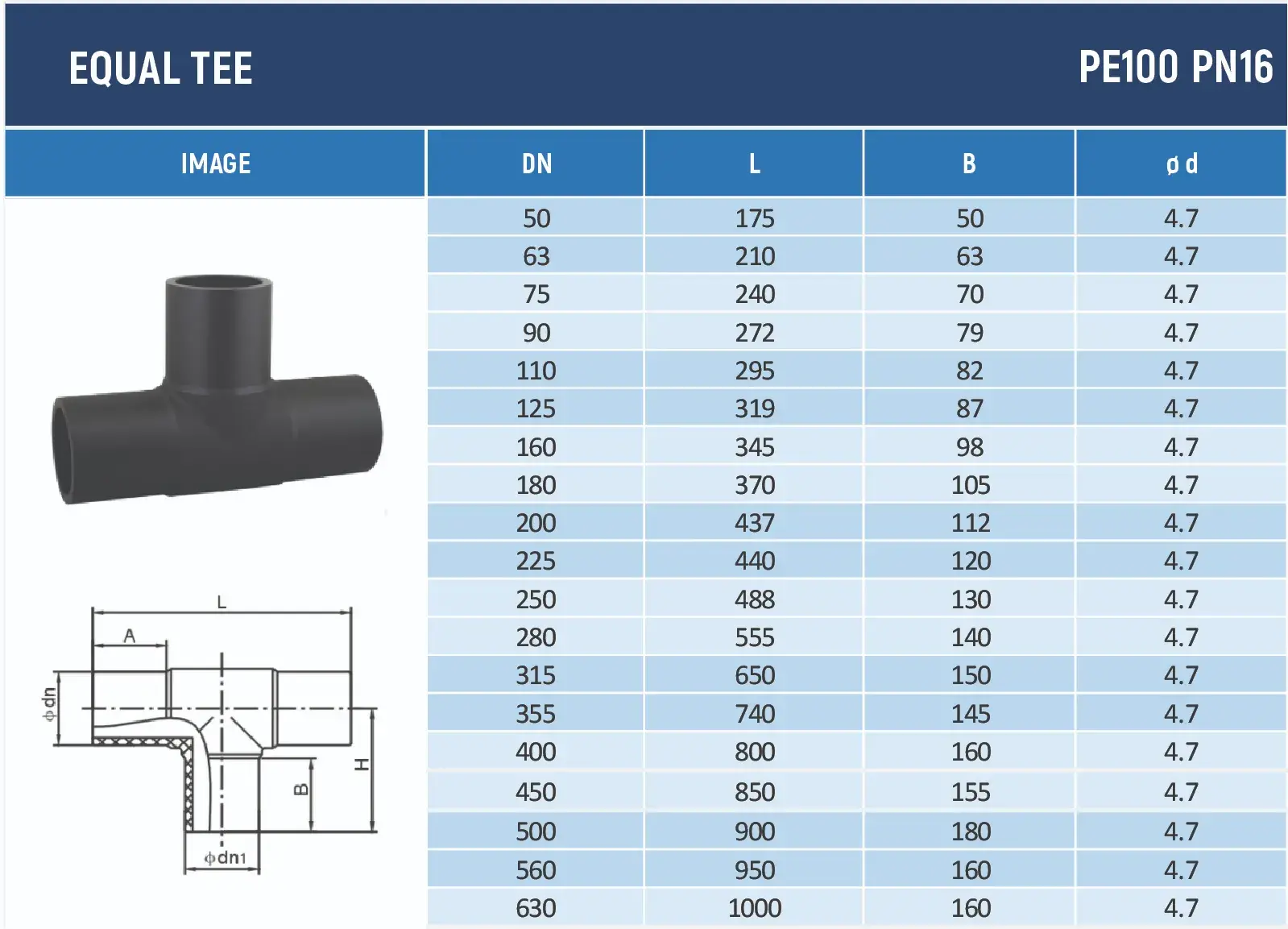

HDPE butt fusion equal tee is one of three main methods of connecting the pipes, The consultant engineer will determine the pipe connection method according to the facilities available at the time of work in the specifications of the design. At the moment, the butt fusion connection is used for the main projects of HDPE piping and the flange connection is used for special fittings. PE butt fusion fitting will reached a solid connection to avoid leakage, on the other hand, compared with socket fusion fittings, the maxmum size of butt fusion equal tee can reached to 800mm and satisfy some projects which need large dimensions.

HDPE butt fusion equal tee is a fitting used in high-density polyethylene (HDPE) piping systems to connect three sections of pipe at a 90-degree angle, creating a “T” shape. This fitting is commonly used in industries like water supply, gas distribution, and wastewater management, among others.

The main features of HDPE butt fusion equal tee

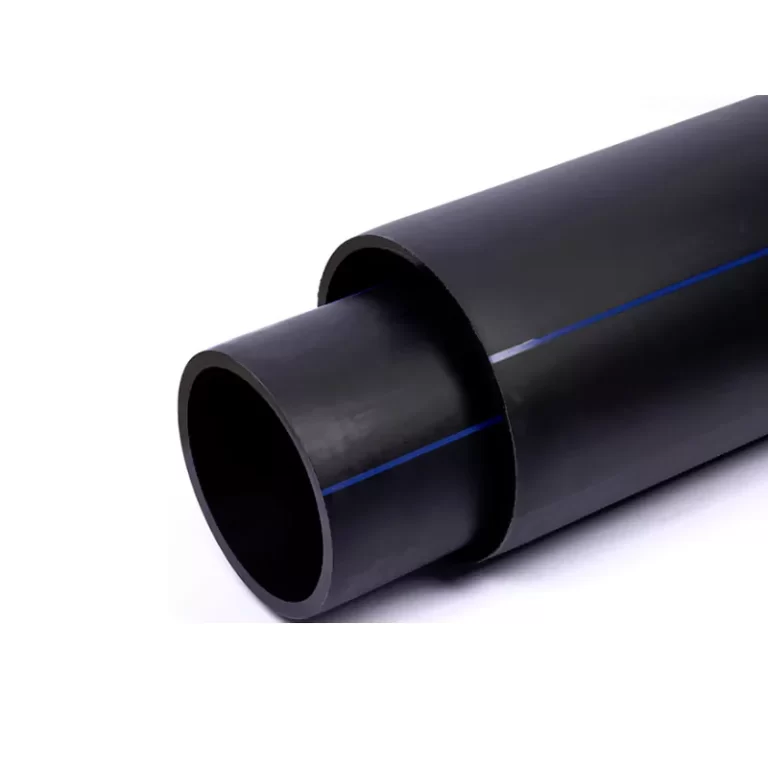

- Material: High-Density Polyethylene, which is durable, corrosion-resistant, and suitable for various applications such as water supply, gas distribution, and industrial pipelines.

- Butt Fusion Jointing:

- Uses heat and pressure to join the tee to the HDPE pipes, creating a seamless and strong bond.

- Requires specialized butt fusion equipment for heating and aligning the pipes and fittings.

- Equal Tee: The term “equal” indicates that all three openings of the tee are the same diameter, ensuring uniform flow distribution.

The installation of HDPE butt fusion equal tee

- Preparation: Clean and align the pipe ends and the fitting.

- Heating: Use a butt fusion machine to heat the ends of the pipes and the fitting until they are molten.

- Alignment and Fusion: Press the heated ends together and hold them in place until the joint cools and solidifies.

- Inspection: Verify the joint quality by checking for proper alignment and uniform bead formation.