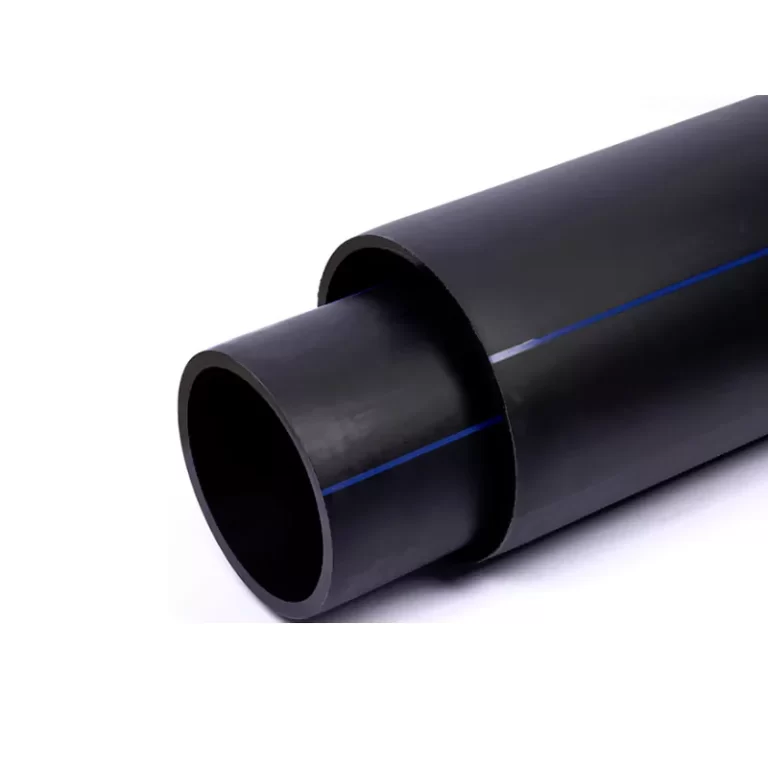

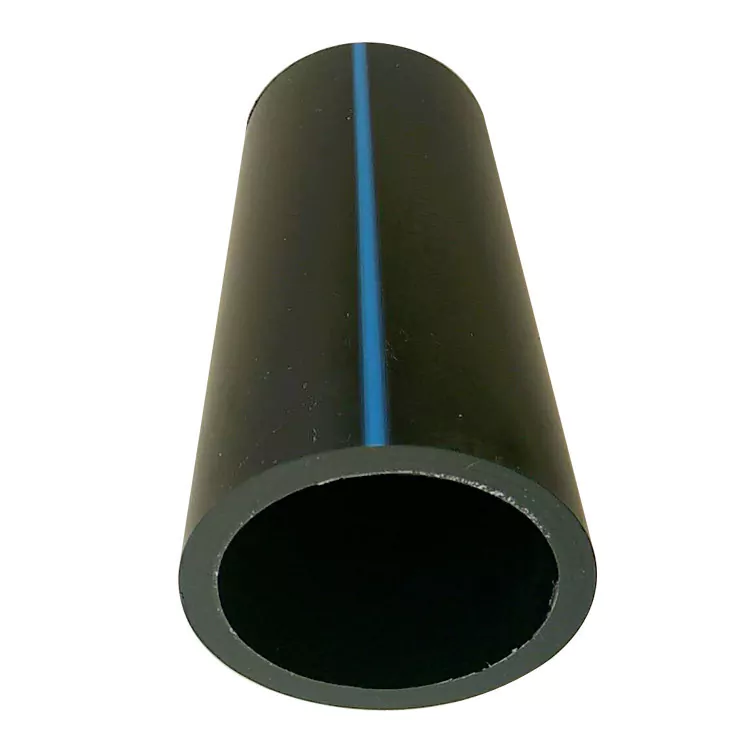

HDPE Conduit Cable Pipes are specially designed to be communication optical(electric) cable protection tubing. The silicon core pipe is produced and shaped through an extruding synchronization with the silicon core material and a low friction coefficient inside the HDPE pipe . Because of that ,the HDPE conduit cable pipe provides excellent covenience for cable laying due to the durability and low friction coefficient inside the lubricating solid tunnel. It is among the most advanced methods for optical cable protection in the world today.

HDPE (High-Density Polyethylene) conduit cable pipe is a type of piping commonly used in electrical, communication, and other utility installations. It is made from high-density polyethylene, a durable plastic known for its toughness, flexibility, and resistance to corrosion. HDPE conduit is designed to protect cables and wires from environmental damage, physical stress, and moisture.

The Key Features of HDPE Conduit Cable Pipe:

- Durability: HDPE is resistant to impact, chemicals, and UV rays, making it suitable for both underground and above-ground installations.

- Flexibility: HDPE conduit can bend around corners and obstacles without breaking, which makes it ideal for installations in complex environments.

- Corrosion Resistance: Unlike metal conduits, HDPE does not corrode, making it ideal for use in areas with high moisture or in coastal environments.

- Lightweight: It is easier to handle and install compared to rigid materials like steel or PVC.

- Smooth Interior: The smooth walls of HDPE conduit reduce friction, which helps with the easier pulling of cables and wires through the pipe.

- Long Lifespan: HDPE is highly durable, with a service life that can exceed 50 years when installed properly.